Portfolio

We have developed over 120 projects across various sectors of the national and international industry. Explore our portfolio and challenge us with your project!

Production Lines

We develop automatic production lines for the complete or partial assembly of various products.

A production line can integrate multiple cells, peripherals and automatic equipment as well as manual stations. It usually includes quality control and packaging.

Robotic cells

We develop production cells for automating manufacturing processes, quality control, and packaging. A production cell automates a specific part of the production process, usually integrating quality control of the operations performed and can also carry out intermediate packaging to deliver parts to the next process.

Robotic Cell for Tape and Pull-Tab Application

AG97 | Tape and Pull-tab Application

Custom-Designed Robotic Tape Application Cell for Automotive Sector – Pillar A & B Front and Back.

The cell is equipped with a dynamic tension control system to ensure proper tape tension and enhance application quality.

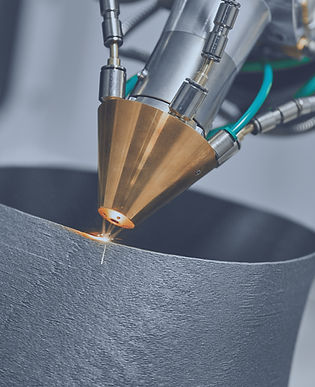

Equipment and Peripherals

We consider innovation to be essential for improving production processes and increasing competitiveness. In this regard, we actively participate in research and development projects in the fields of robotics, additive manufacturing, and artificial vision.

Extrusion of reinforced cement mortars

AG106 | Concrete 3D Print Robotic Cell

Equipment designed for extruding reinforced cement mortars.

Enabling 3D printing in construction and architectural design.

The extruder provides reinforcement orientation according to the ideal impregnation vector, through an infnite rotating head, and is also equipped with a quick reinforcement exchange system.

Artificial Vision

Development of quality control and artificial vision systems, based on rules and deep learning, to control production processes and assemblies.

Research and Development

We consider innovation to be essential for improving production processes and increasing competitiveness. In this regard, we actively participate in research and development projects in the fields of robotics, additive manufacturing, and artificial vision.

Recovery – Resilience – Reindustrialisation

PRR - Produtech - CePHIM

This project focuses on developing and applying Friction Stir-Welding (FSW) to create hollow cooling channels for optimised mould refrigeration. As part of this initiative, a telemetry system will be developed to monitor and optimise the process, collecting critical data such as temperature and working forces.

Additive Manufacturing of Reinforced Cementitious Structures

PT2020 - 3DFiber.concrete

The 3DFiber.concrete project aims to respond, on the one hand, to the limitations related to the incorporation of mechanical reinforcement in structures manufactured by FA for the construction sector and, on the other, to the need to automate and automate processes through the use of robotic systems.

Organisational and Process Innovation

SI-IP | Industria 4.0

With this project, AGIX aims to strengthen its digitalisation process. The adoption of new technologies and digital methodologies, as outlined in the proposal, will enable the company to enhance control and improve efficiency across various tasks within its production process.